In recent years, covalent organic framework (COF) membranes have emerged as a revolutionary technology in the field of energy-efficient molecular and gas separation. These membranes are considered ideal for industrial applications due to their highly ordered pore structure, chemical stability, and customizable design. However, precise channel size control at the sub-nanometer level (0.3–0.5 nm) required for gas separation has remained a major challenge so far. The pores of commonly available COF membranes range from 0.6–10 nm, which are too large for effective filtration of common gas molecules.

Novel approach: “pore-in-pore” engineering

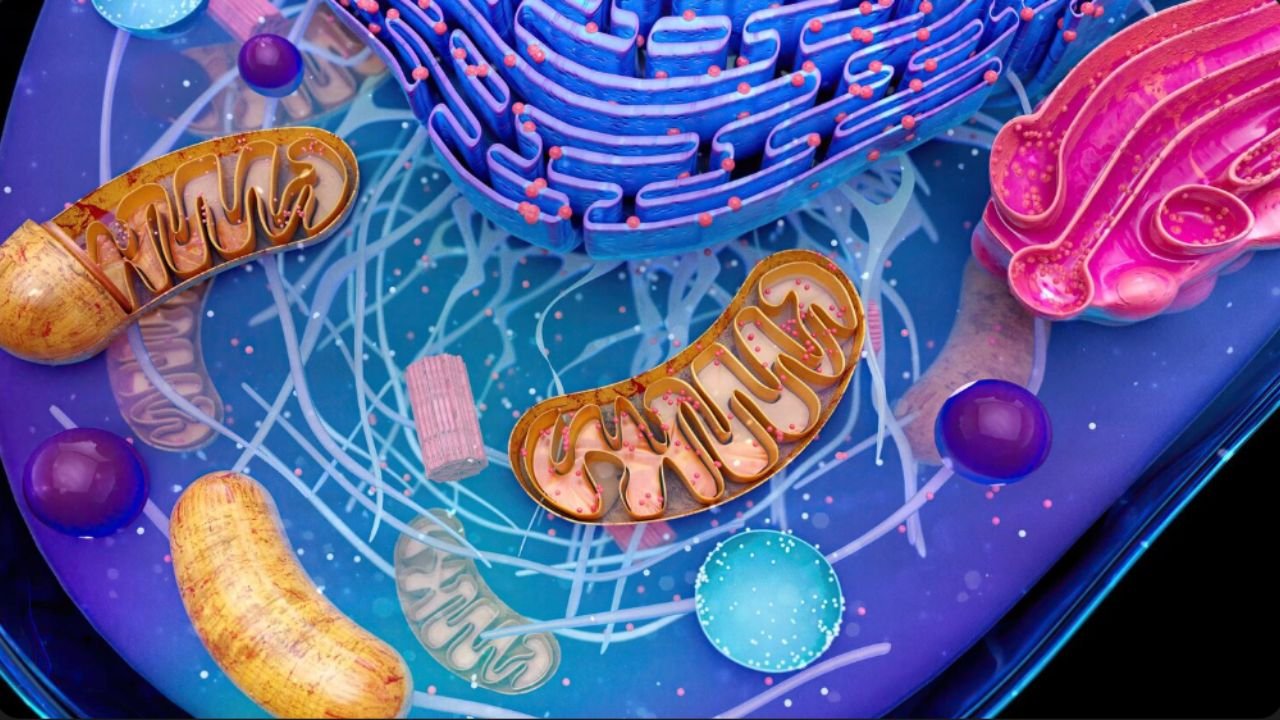

To address this problem, scientists have developed a novel “pore-in-pore” strategy. The concept uses a molecule called α-cyclodextrin (α-CD), which is shaped like a tiny cylinder and provides an ultramicro-pore (0.47–0.53 nm) inside it. It is incorporated within the larger nano-pores (∼1.8 nm) of the COF membrane to form a “matryoshka”-like multi-layered structure.

Under this technique, α-CD was incorporated into the TpPa-1 COF membrane during the interfacial polymerization process, causing it to be systematically located within the 1D nanochannels. It was subsequently subjected to epichlorohydrin (ECH) treatment, which formed stable linear assemblies (LA) between α-CD molecules and developed stable, highly-selective gas transport pathways.

Structural and Chemical Characterization

The color change (from white to dark red) of the newly prepared membrane proved its successful structure by SEM and XRD analysis. Fluorescence imaging made it clear that α-CD was evenly dispersed throughout the COF network. BET analysis showed a reduction in surface area compared to conventional TpPa-1, proving that α-CD had filled the larger pores and converted them into ultramicro-pores.

Excellent Performance in Gas Separation

This membrane exhibited extremely high permeability (~3000 GPU) for H2 gas and more than 30 selectivity over CO2 and CH4. Its efficiency in mixed gases (H2/CO2, H2/CH4) was also far superior to other existing membranes. Importantly, this performance was above the Robeson upper bound, which is considered the highest standard for gas separation membranes.

Durability and practical prospects

The membrane remained stable not only at normal temperatures but also at high temperatures up to 180°C and 6 bar pressure. There was no degradation in its efficiency even after long-term operation (up to 60 hours). Additionally, the membrane also exhibits high efficiency in dye wastewater filtration and ion interception, indicating its potential for multipurpose use.

Mechanism of gas transport: insights from molecular dynamics simulations

Molecular dynamics (MD) simulations showed that H2 molecules pass through two major pathways – (1) through the internal channel of α-CD and (2) through the narrow space between the COF wall and α-CD. In contrast, CO2 molecules remain adsorbed on the membrane surface for a longer time, slowing down their flow. This is a clear example of competitive diffusion, where smaller H2 molecules pass faster than larger molecules.

Conclusions and future directions

This development of LA-α-CD-in-COF membrane is an important milestone in gas separation technology. Its high efficiency, durability, and multipurpose potential make it highly promising for industrial gas purification, hydrogen production, and energy-efficient separation processes. In the future, this strategy can be expanded to other types of COF membranes and molecular separation applications, helping to achieve the goals of clean energy and environmental sustainability.