Today, science and technology are constantly advancing, and every day something new is coming out. A very special discovery has been made in the direction of this progress – gas-responsive smart membrane. This technology is much more advanced and intelligent than traditional membrane separation techniques. Let’s understand it in simple language and know what it is, how it works and what its future may be.

What is membrane separation?

First of all, it is important to know what membrane separation is.

A membrane is a thin layer that works to filter, separate or filter different substances from any mixture. For example, a special type of membrane is used in RO water purifiers that removes impurities from water and gives clean water.

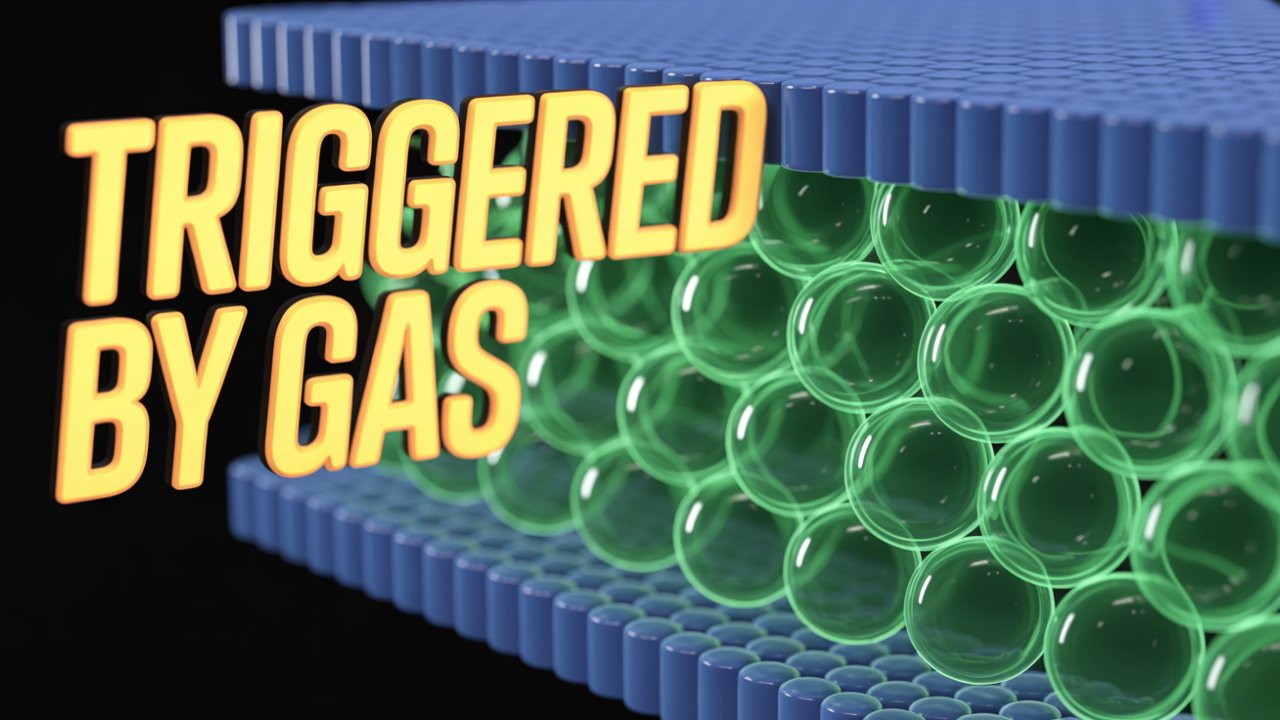

Traditional membrane technologies are static, meaning their filtering capacity and pore size remain constant. But science has made it smarter. Membranes are now being developed that can automatically change their pore size and control surface properties based on external signals or stimuli.

Gas-Responsive Membranes: A Smart Move

Now the question is, what are gas-responsive membranes?

These are membranes whose pores and surface properties change when exposed to a gas. That is, when a particular gas is added to them, they can reduce or enlarge their pore size, making the surface hydrophilic (water-attracting) or hydrophobic (water-repelling).

This ability makes them smart, as they can adjust themselves according to different conditions.

Why is this technology special?

There are many reasons why this technology is considered very special –

- Clean and safe – Using gas as a trigger is safe and clean. No toxic or harmful elements are formed.

- Biocompatible – This means that it can also be used in processes related to biology, such as controlled drug delivery.

- Easy operation – The gas is easy to use, it does not require a more complex mechanism.

- Non-destructive – That is, it does not damage the structure of the membrane.

How are gas-responsive membranes made?

Scientists adopt different fabrication techniques to make these membranes.

Some major methods are –

- Polymer coating technique – In this, a layer of gas-sensitive polymer is applied on a base membrane.

- Use of nanomaterials – Nanoparticles are included to make the membrane more sensitive.

- Layer-by-layer assembly – In this technique, a multi-functional membrane is prepared by joining several thin layers.

Where can they be used?

1. Controlled Cargo Release

Suppose a drug has to be delivered to a specific part of the body and released there at a specific time. Gas-responsive membranes make this possible. When the gas is triggered, the membrane opens and the drug comes out.

2. Size-/Charge-Based Separation

This membrane is so precise that it can separate even very small particles based on their size and electrical charge.

3. Oil-Water Separation

It is difficult to separate the mixture of oil and water in industrial waste. But these smart membranes can do this work easily.

4. Self-Cleaning

Many membranes become blocked by dirt accumulation over time. But gas-responsive membranes can keep themselves clean, as the gas trigger keeps their pores open and the surface clean.

Challenges and Future Prospects

Although this technology is extremely promising, there are still some challenges –

- Production cost – Right now these membranes are expensive to make.

- Long-term stability – Whether these membranes will remain durable when exposed to gas for a long time is a big question.

- Industrial-level testing – So far it has been mostly tested at the laboratory level, more research is needed for large-scale use.

In the future, when production costs will be lower and the technology will be more sophisticated, these membranes can be used in water purification, medical industry, chemical processing, even space missions.

Conclusion

Gas-responsive smart membranes are a discovery of modern science that can revolutionize traditional separation techniques. Its smartness, safety and flexibility can make it an important part of future industries. In the coming years, this technology will not only be limited to laboratories but will play a big role at both industrial and domestic levels.