As the world is moving towards energy efficient, environmentally friendly and cost effective technologies, “Membrane-Based Gas Separation Technology” is emerging as a major innovation. This technology uses a special type of membrane to separate industrial gases from each other. But as much as there is advancement behind this technology, there are also as many challenges. In this article, we will discuss in detail those major challenges and possible solutions to overcome them.

What is Membrane Based Gas Separation?

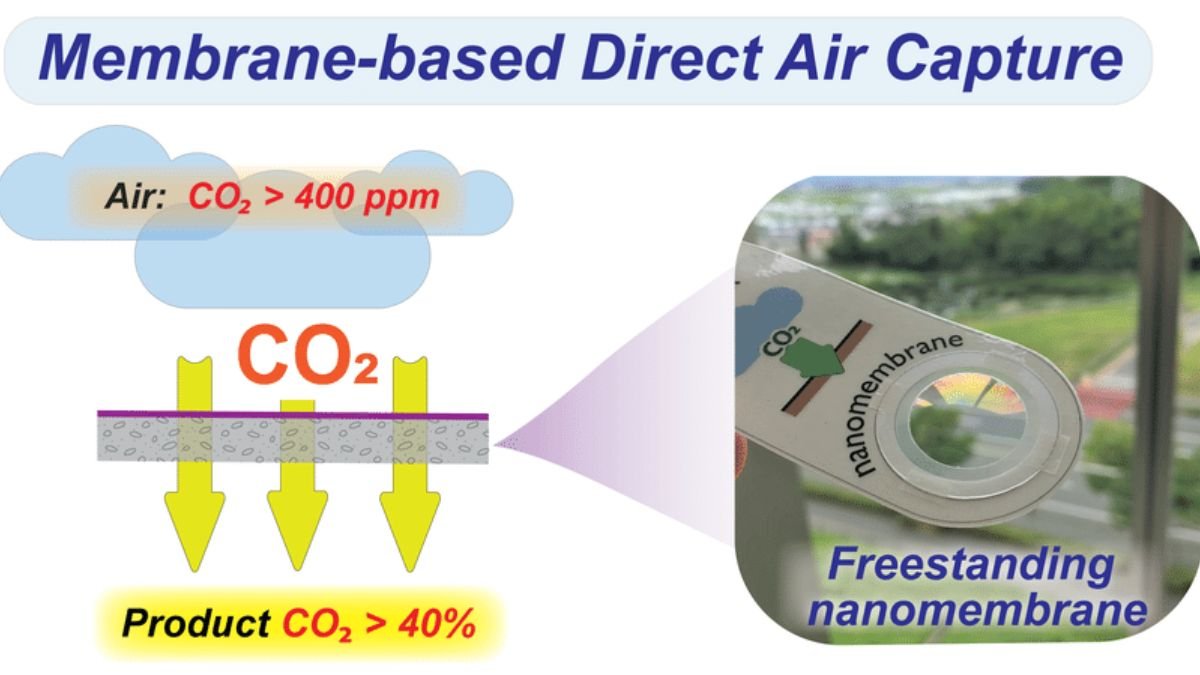

Membrane-based gas separation is a process in which a gas mixture is passed through a membrane, and different gases pass through the membrane at different rates. This technology is considered especially useful for carbon dioxide separation, hydrogen recovery, natural gas cleaning and air separation.

Key features of this technology

- Energy Efficient: Less energy consumption compared to other conventional methods.

- Environmentally friendly: Low carbon footprint.

- Small size and portable design

- Easy to operate and maintain

But is this technology perfect?

No. There are many technical, physical and economic challenges in the development and commercial use of membrane-based technology. Let us now discuss these major challenges one by one.

Challenge 1: Selectivity vs Permeability

Problem:

Membranes have two main properties—permeability (how easily a gas passes through) and selectivity (how well the membrane can separate one gas from another). But balancing both properties is very difficult. Most membranes are either highly permeable or highly selective, but not both.

Solution:

- Development of novel materials such as polymers and nano-composites.

- Use of multi-layered membranes.

- Use of hybrid membranes that combine two types of materials.

Challenge 2: Long-term stability and durability

Problem:

Many membranes lose their properties over time—such as fouling, plasticization, thermal degradation. This reduces their efficiency.

Solution:

- Use of membrane materials that are chemically and thermally stable.

- Use of coating techniques on the membrane, such as polymer brushes or carbon layers.

- Monitoring of operational conditions and regular maintenance of the membrane.

Challenge 3: Performance at high pressure and temperature

Problem:

Membranes are often used in industries at high temperatures and pressures, but most membranes do not perform under these conditions.

Solution:

- Development of ceramic-based membranes or metal-organic framework (MOF) membranes.

- Use of thermally stable polymers.

- Plant designs that control operating conditions.

Challenge 4: Cost and scalability

Problem:

High quality membranes are expensive to manufacture and implementing them on a large industrial scale can be economically challenging.

Solution:

- Large scale production of affordable materials.

- Automated manufacturing processes.

- Joint R&D efforts by government and industries.

Challenge 5: Complexity of gas mixtures

Problem:

Industrial gas mixtures often contain multiple components, with some unwanted elements affecting membrane functionality.

Solution:

- Use of primary gas pre-treatment processes.

- Designing membranes for specific gases.

- Smart membrane systems with automatic controls.

Modern innovations that are making this technology even better

- Use of Artificial Intelligence and Machine Learning in membrane design and performance prediction.

- Bio-inspired membranes such as those that are inspired by nature for gas separation.

- Dynamic membranes that adjust themselves according to changing conditions.

Prospects of Membrane-based Gas Separation in India

India has a huge use of industrial gases—in cement, steel, refineries, power plants, etc. Membrane technology can bring a revolutionary change in India. Many Indian institutes such as IITs, IISc, and BARC are doing research in this direction.

Conclusion

Membrane-based gas separation technology has brought a new revolution in the world of science and industry. Though it faces many challenges, continuous innovation, scientific research, and better policy-making can enable this technology to meet future energy requirements efficiently.