From water purification to chemical processing in industries, membrane technology has become an integral part of today’s world. Whether it is reverse osmosis (RO) plants or wastewater treatment, membranes are being used everywhere. But this technology has a big enemy – membrane fouling.

If you are associated with the water treatment industry or are interested in this technology, then this article will give you a quick but in-depth review of the causes of membrane fouling, its harmful effects and the new technologies being used to prevent it.

What is membrane fouling?

In simple words, membrane fouling means the accumulation of unwanted particles, bacteria, chemicals or other things on the surface of the membrane, which reduces its ability to filter water or fluid.

Think of it like your home water filter slows down over time, as dirt accumulates in its membrane. At the industrial level, this problem occurs on a very large scale and due to this the efficiency of the system starts falling.

Main types of membrane fouling

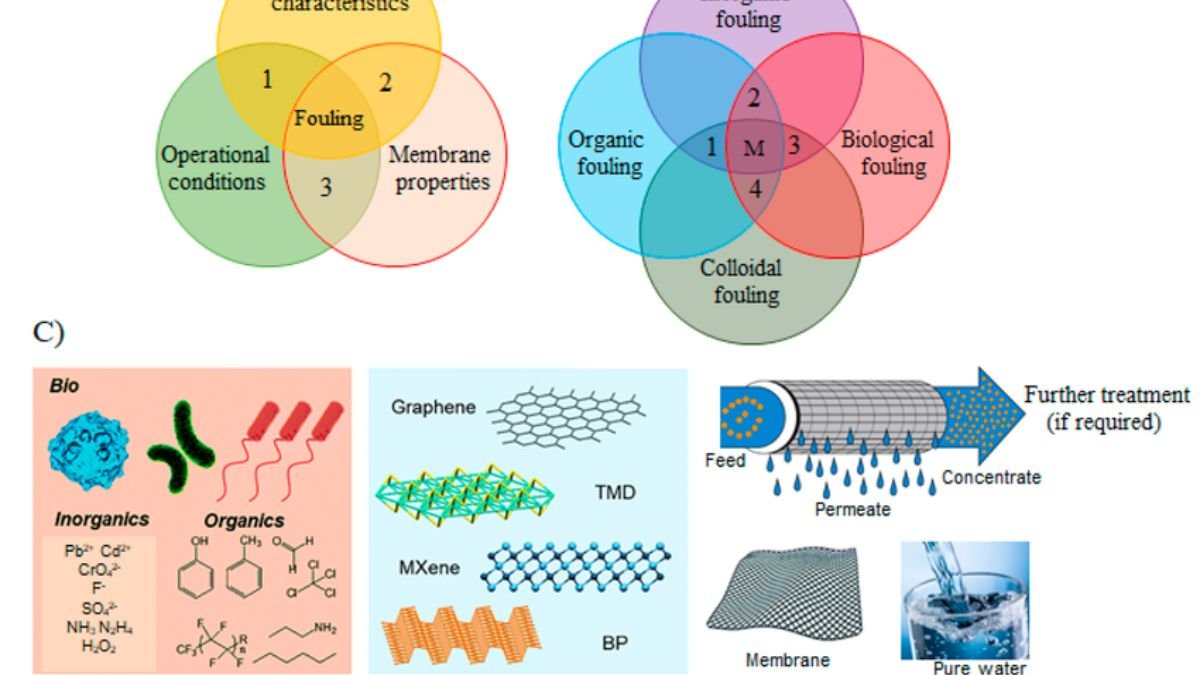

There are many types of membrane fouling, and each type of problem is different –

- Biofouling: Accumulation of microorganisms, bacteria and their biofilm on the membrane.

- Scaling: Accumulation of minerals such as calcium, magnesium or silica present in water.

- Particulate Fouling: Accumulation of soil, dust or other solid particles.

- Organic Fouling: Accumulation of dissolved organic material such as oil, grease, humic acid in water.

Each type of fouling requires different cleaning techniques and prevention methods.

Why does membrane fouling occur? – Main reasons

There are many reasons behind this:

- Poor water quality (high TDS, organic matter, bacteria).

- Lack of proper pre-treatment which allows large particles to reach the membrane directly.

- Operating condition disturbances such as pressure, pH and temperature not being controlled.

Irregular cleaning schedules which lead to the deposition on the membrane continuously increasing.

Hazardous effects of fouling

Membrane fouling is not just a technical problem, but it also has economic and environmental implications –

- Decrease in efficiency: The rate of water filtration decreases.

- Increase in operating costs: More pressure and pumping is required.

- Increase in energy consumption: Electricity bills increase.

- Reduced membrane life: Requires early replacement.

- Decrease in water quality: Impurities may increase in the output water.

Challenges of fouling in industry

Many industries, such as desalination plants, pharmaceutical manufacturing and food processing, depend on membrane technology.

But fouling causes –

- Production slows down.

- Quality standards are not met.

- Pressure on the maintenance team increases.

- Unwanted downtime leads to financial losses.

Traditional cleaning techniques

Till now, chemical cleaning has been mainly used to deal with fouling.

- Acid cleaning: To remove scaling.

- Alkaline cleaning: To remove organic deposits.

- Use of biocides: For biofouling.

However, excessive use of chemicals can also damage the membrane and also impact the environment.

Modern and cutting-edge solutions

Today technology has advanced so much that there are many cutting-edge solutions available to prevent and reduce fouling:

- Anti-fouling coatings: The membrane surface is made in such a way that dirt does not stick to it.

- Online cleaning system: Cleaning without shutting down the system.

- Advanced pre-treatment: Use of ultrafiltration, microfiltration first.

- Smart sensors and AI monitoring: Alerts as soon as fouling occurs.

Emphasis on prevention – better than cure

Preventing membrane fouling is easier and cheaper than removing it later.

- Chemical and physical analysis of inlet water.

- Installation of raw water pre-treatment system.

- Regular flushing and CIP (Clean in Place) program.

- Monitoring of operation parameters.

Future of membrane fouling management

In the coming times, next-generation membranes will come which will be automatically fouling resistant.

- Graphene-based membranes – more smooth and durable.

- Nanotech coatings – capable of stopping dirt at the micro level.

- AI predictive analytics – signal before fouling occurs.

Conclusion

Membrane fouling is a big challenge for both water treatment and industry.

If the causes are identified at the right time, the right prevention techniques are adopted and modern solutions are used, not only the life of the system can be increased but both energy and cost will be saved.

Finally, remember – clean membrane, better water, happy system