Membrane technology is used today in a wide range of fields, from water purification to pharmaceuticals, food processing and industrial separations. But when it comes to removing non-charged solutes (i.e. particles or molecules that have no electrical charge), the challenges increase. Non-charged particles behave differently than charged particles, and the usual electrostatic repulsion or ion exchange mechanisms do not work to trap them.

In this article, let us understand what these challenges are and how new solutions are being developed for them through 10 key points.

Why is it so difficult to remove non-charged solutes?

Non-charged solutes have no electric charge, so they mix easily with water or other solvents and have no obvious reason to stick to the membrane surface.

Charge-based filtering can be achieved on membranes for charged particles, but the capture of neutral molecules depends on size, morphology and hydrophobic-hydrophilic interactions.

This is why standard nanofiltration or reverse osmosis membranes are not always perfect for these solutions.

Limitations of conventional membrane technology

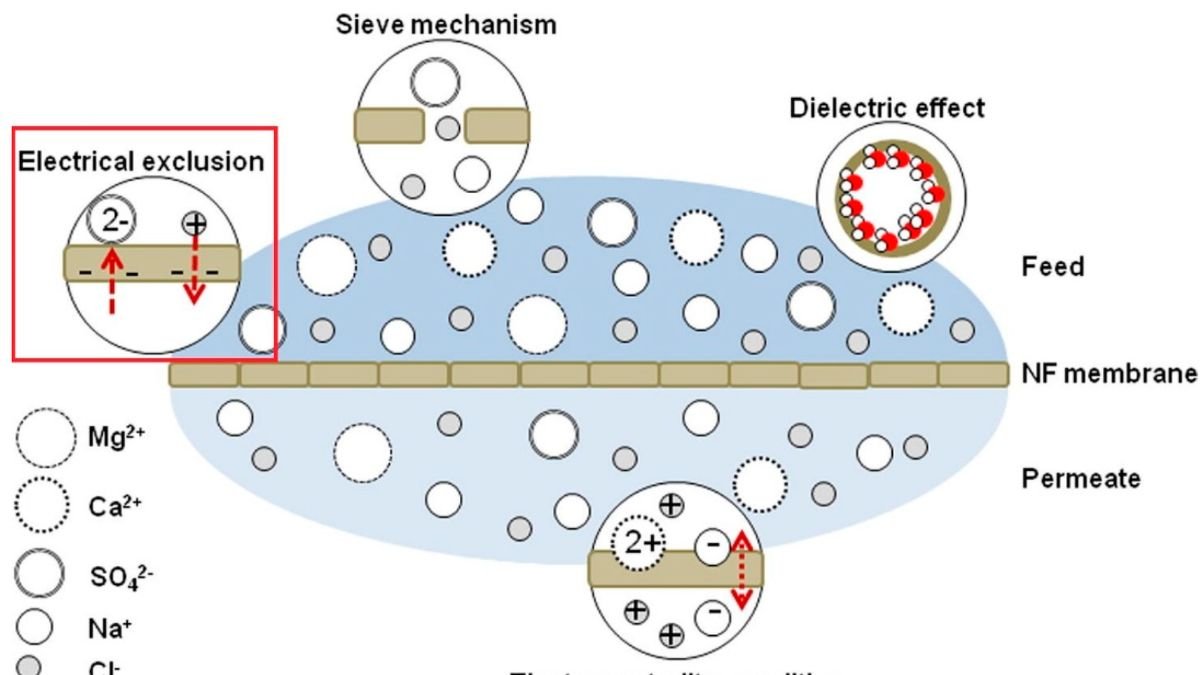

Conventional membrane technologies are mostly designed for charge separation. The pores in nanofiltration (NF) and reverse osmosis (RO) are small enough to trap larger non-charged particles, but smaller molecules such as alcohols, sugars or some organic compounds pass through easily.

In addition, fouling and scaling of membranes also occurs differently with non-charged particles, reducing their efficiency.

Role of hydrophobic and hydrophilic interactions

The performance of membranes with non-charged solutions depends largely on whether the membrane surface is hydrophobic (water repelling) or hydrophilic (water attracting).

For example, hydrophobic membranes are better at trapping non-charged particles dissolved in organic solvents, while hydrophilic membranes are better at trapping water-based mixtures.

Challenges of size-exclusion mechanisms

Size-exclusion, i.e., trapping particles based on their size, is an important technique in the case of non-charged solutes. However, if the size of the non-charged solute is equal to or smaller than the pores of the membrane, it can easily pass through.

This means that the pore size of the membrane must be very precise, but this can also lead to a reduction in the flow of water or solvent, which is detrimental for industrial processes.

Membrane fouling and its complexities

Non-charged solutes often adhere to the membrane surface, causing fouling. Hydrophobic solutes, in particular, can penetrate the membrane layers and reduce its efficiency.

Preventing fouling requires frequent cleaning, but frequent cleaning reduces the life of the membrane and increases the operation cost.

New membranes made of advanced materials

In recent years, scientists have developed advanced materials that are better at removing non-charged solutes. These include graphene oxide membranes, carbon nanotube membranes, and modified polymer membranes.

These membranes not only provide precise pore size control but the surface chemistry is designed in such a way that it can interact better with non-charged solutes.

Surface modification techniques

The hydrophobic-hydrophilic nature of the membrane can be changed by applying special coatings on its surface or by chemical modification.

This allows the membrane to be tuned for specific non-charged solutes, thereby increasing the separation efficiency and reducing fouling problems.

Use of hybrid filtration systems

A new solution is to combine membrane filtration with other technologies such as adsorption, activated carbon filters or advanced oxidation processes.

Such a hybrid system first partially removes the non-charged solute and then performs fine separation from the membrane, thereby increasing both efficiency and life.

Balance of energy efficiency and cost

The biggest challenge in new solutions is to keep the cost low while also achieving high efficiency. Advanced materials and hybrid systems, while improving performance, can be costly. Hence, the industry is now working towards designs that are long-lasting, low-maintenance and energy-efficient.

Future Direction – Smart and Responsive Membranes

Membrane technology may get even smarter in the future. Researchers are working on membranes that can change their pore size and surface properties according to their environment.

Such responsive membranes will not only be better at removing non-charged solutes, but will also have a longer lifespan due to features like auto-cleaning and self-repair.

Conclusion

Removing non-charged solutes using membrane technology is a complex but important process. Despite the limitations of conventional methods, new solutions like advanced materials, surface modification, hybrid filtration and smart membranes are revolutionising this direction. In the coming years, these technologies will not only transform industrial processes but will also be a major catalyst for improving the efficiency of membranes.