The use of membranes in water purification technology is not new, but when it comes to hypersaline environments, the story becomes quite challenging. In such environments, normal membranes deteriorate quickly, their efficiency decreases and the cost also increases. This is why scientists around the world are constantly doing research in this field.

In this blog, we will understand in 10 key points what is happening in membrane research for hypersaline environments and why this technology is important for our future.

What is a hypersaline environment and why is it a challenge?

A hypersaline environment is one in which the salt content in water is extremely high — often even more than seawater. This condition is found in natural lakes, brackish groundwater and many industrial wastewater sources. Due to such high salinity, traditional methods of purifying water fail. Membrane technology may be useful here, but conventional membranes do not last long in such environments.

Basic concept of membrane technology

A membrane is a type of semi-permeable membrane that allows water to pass through but traps salt and other impurities. Reverse osmosis (RO) is the most popular form of this, in which water is forced through a membrane using high pressure. The process is even more difficult for hypersaline water as the higher salt content increases pressure and energy consumption.

Limitations of existing membranes

Conventional RO membranes are designed for salt levels of up to 3–4%. But in hypersaline environments, the salt content can be as high as 10% or even more. At this high salinity, the membrane breaks down quickly, water recovery rates drop and operating costs skyrocket. This is why researchers are working on more durable and high-performance membranes.

New research focus – sustainable and energy-efficient membranes

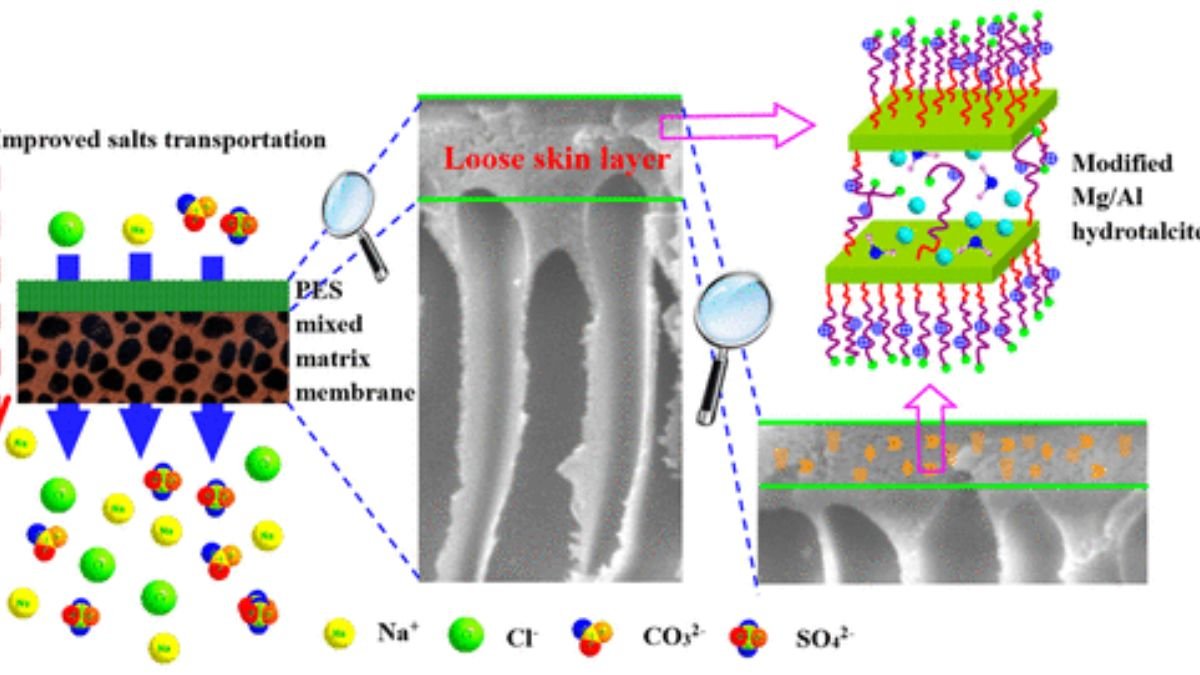

Research teams around the world are designing membranes that not only tolerate saltiness but also work better with less energy. Nanomaterials, graphene and advanced polymers are being used for this. These make the membranes stronger and special coatings are applied on their surface so that salt does not freeze and damage them.

Increasing use of nano-engineering

Nanotechnology is revolutionizing this field. By adding nanoparticles to the surface of the membrane, their permeability, durability and anti-fouling capacity are being increased. Some research has used silver nanoparticles and carbon nanotubes, which prevent bacterial growth and maintain water purity.

Strategies to reduce energy consumption

The biggest cost in purifying hypersaline water is energy, because the pressure required is very high. New membrane designs are focusing on reducing this pressure by developing low-pressure high-performance membranes that can achieve high salt removal with less energy. Some research is also using forward osmosis and hybrid systems to reduce energy consumption by 20–30%.

Use of membranes in industrial wastewater

Hypersaline wastewater is a major problem in industries such as oil and gas, chemical, and mining. New membrane technologies are being tested in these places to make water reusable. This will not only help protect the environment but also reduce the industry’s dependence on water.

Pilot projects and real-world testing

Pilot projects are underway in several countries where new membranes are being tested near the sea, near salt mines, or in industrial waste plants. The purpose of these projects is to see whether the technology that has been successful in the lab is equally effective in the real world. Initial results are encouraging — some membranes have worked for more than 6 months without breaking down.

Environmental benefits and sustainability

If sustainable membranes for hypersaline environments become available, it will be a game changer for the environment. It will reduce the need to dump untreated saline water into the ocean, improve groundwater quality, and provide new water sources to water-scarce regions. Also, carbon emissions will decrease due to reduced energy consumption.

Future direction – low cost and mass production

The biggest challenge for these advanced membranes right now is their cost. The next step for researchers is to develop manufacturing technology that can produce these membranes at a low cost and on a large scale. In the next 5–10 years, we can expect that purifying hypersaline water will not only be technically feasible but also economically feasible.

Conclusion

Purifying water in hypersaline environments is a complex but extremely important task. New discoveries in membrane technology are moving us rapidly in this direction. Nanotechnology, energy efficiency, and new strategies for industrial waste management can play an important role in solving the water crisis in the future. If this research moves in the right direction, the coming decade will be called the decade of “affordable and sustainable water purification technology”.